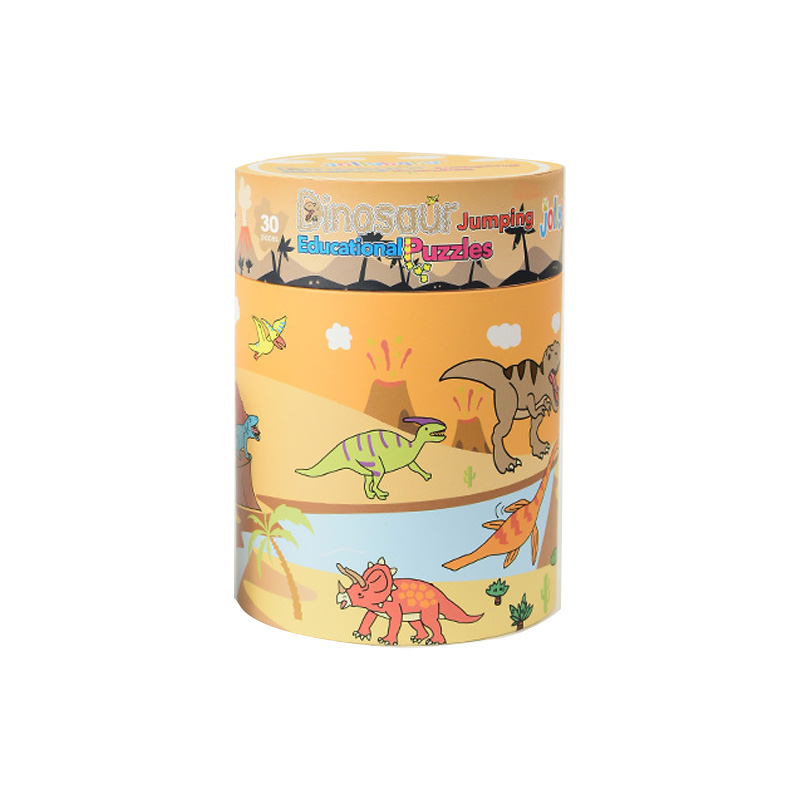

This paper tube packaging adopts a cylindrical three-dimensional structure, which creates a differentiated visual impact from traditional square packaging. It has a stable structure and high space utilization, which is convenient for stacking and transportation, reducing the risk of damage. At the same time, the special-shaped box type (such as layered and detachable design) meets high-end customization needs and supports high customization of box type, material, process, printing, etc. to meet your packaging needs.

Facebook

Twitter

LinkedIn

1. Innovative cylindrical structure design

- Three-dimensional cylindrical configuration The high-strength cylindrical three-dimensional structure is adopted, which forms a sharp visual contrast with the traditional square packaging. The integrated molding technology of the cylindrical box bottom enhances the sealing and effectively blocks moisture and oxygen. It is suitable for high-end leggings, food and cosmetics that need to be moisture-proof and anti-oxidation. The internal space utilization rate is increased by 15%, which is suitable for the roll-up form of leggings and reduces the risk of wrinkles.

- Smart stacking and modular expansion The cylinder design meets the mechanical load-bearing standards, the stacking stability is increased by 30%, and the transportation damage rate is reduced to less than 1%. It supports layered, detachable liner and other special-shaped customization to meet the high-end needs of gift boxes.

2. Environmentally friendly materials and process technology

| Core elements | Technical parameters and selection |

|---|---|

| Base material | Degradable recycled paper (250-300gsm) / FSC certified corrugated paper |

| Environmentally friendly certification | Comply with EU EN13432 and US ASTM D6400 degradation standards |

| Surface technology | UV local bright film, embossed texture, laser color (supports combined application) |

| Printing technology | Heidelberg CP2000 four-color offset printing ±0.1mm registration accuracy |

3. Visual design system

- Dynamic theme pattern: Using high-saturation orange, green, and yellow collision colors, with the main visual of cartoon dinosaur jumping, the gradient printing technology is used to achieve the depth of field effect of the volcanic cloud layer, and the color difference is controlled ≤5% (Pantone spot color calibration).

- Defect Control: Nano-coating anti-blooming technology is used to ensure that complex patterns have no blurred dots or overflow.

4. Modular customization service

“`plaintext

- Box type adaptation

- Diameter range: Φ50mm–Φ150mm (±1mm error)

- Height layering: basic tube height 80mm, support incremental expansion every 20mm

- Material and process combination

- Recycled kraft paper (matte texture) + hot silver LOGO

- White cardboard (bright surface) + full-page UV + embossed

- Quick response mechanism

- Holiday limited edition: 7-day delivery (including design proofing)

- Joint model: support Pantone spot color + laser process overprinting

5. Manufacturer strength guarantee

- Compliance experience: The technical team is proficient in FDA (US), REACH (EU), GB/T 4857 (China) and other packaging regulations

- Production capacity and quality control: Daily output of 100,000+ boxes, full-link ISO9001 quality management, support cash on delivery balance

6. Traditional square box vs. innovative cylindrical packaging comparison table

| Dimension | Traditional square box | Cylindrical box of this product |

|---|---|---|

| Structural design | Right-angle plane splicing | Streamlined cylindrical one-piece molding |

| Space utilization | ≤85% | ≥95% |

| Sealing performance | Relying on glue sealing, easy to leak | Round bottom seamless pressing, moisture-proof improved by 40% |

| Stacking stability | Easy to tilt and collapse | Concentric circle bite structure, enhanced pressure resistance |

| Visual differentiation | Serious homogeneity | Three-dimensional display surface, shelf recognition rate +70% |

| Environmental protection index | Some plastic coating is difficult to degrade | 100% recyclable materials |

| Customization flexibility | Redesign cycle ≥ 15 days | Modular components delivered in 7 days |