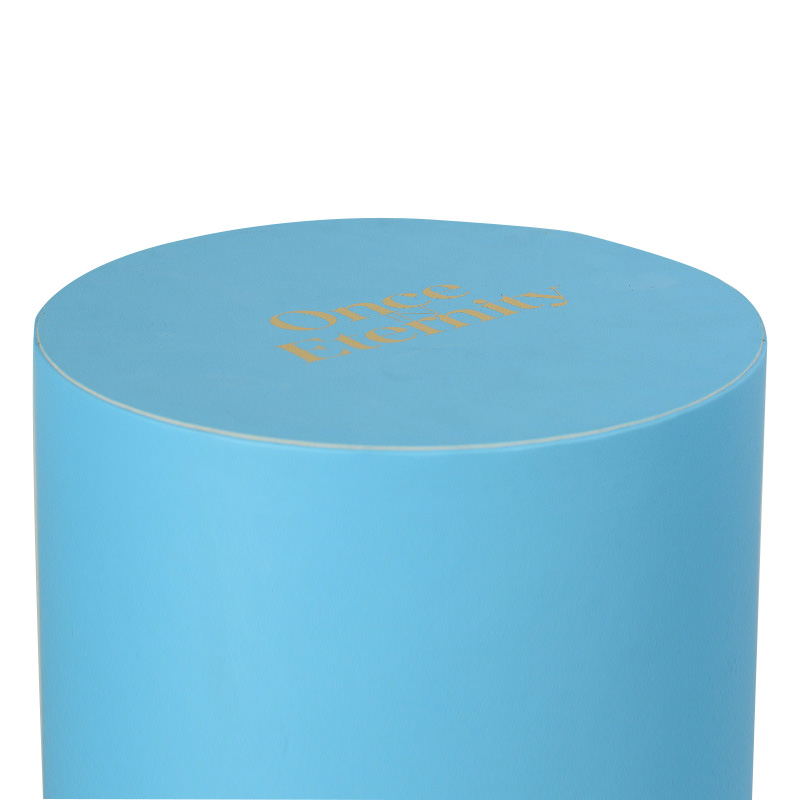

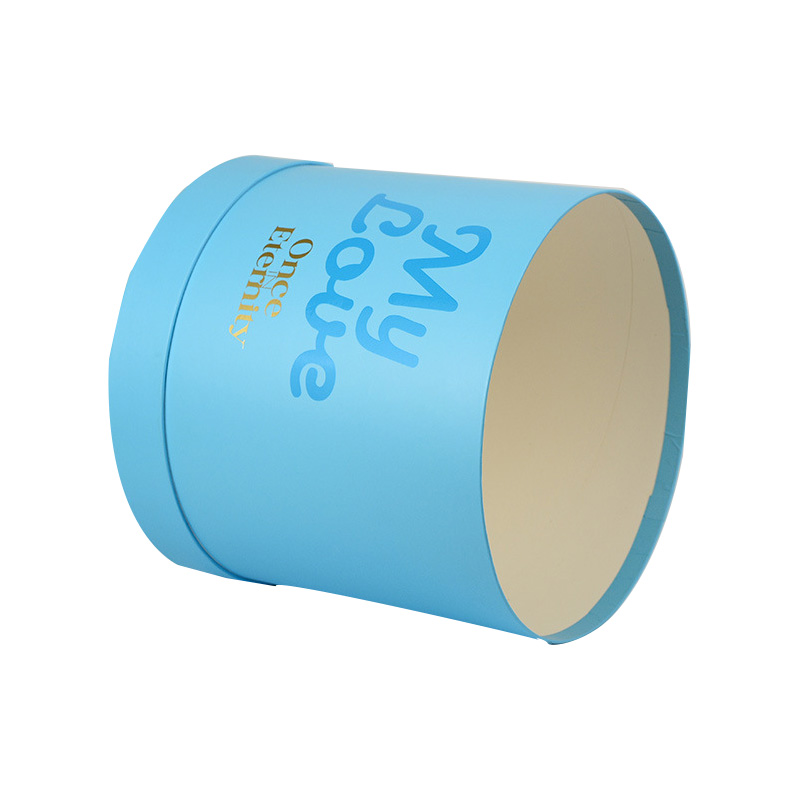

This customized skin care and beauty cosmetics paper tube packaging has a high degree of customization and can fully meet the personalized needs of the brand; 1-hour sample production demonstrates excellent efficiency; FSC, ISO, and BSCI certifications provide authoritative guarantees for quality, environmental protection, and social responsibility; and years of experience are the basis of reliability and professionalism. In terms of specific product presentation, its simple and exquisite cylindrical design, fresh and soft light blue tones, hot stamping technology that enhances the sense of luxury, high-quality materials, and safe linings and exquisite accessories have jointly created a high-quality packaging solution that is visually attractive, high-grade in touch, and can effectively protect the contents and convey brand value.

1. Humanized round style

Comfy hold and convenience of use : The traditional round form is ergonomic, comfy to hold, and the components can be quickly ejected with one hand, which improves the customer experience. Aesthetic simplicity and smoothness : Simple lines and smooth contours resemble the elegant and soft brand name tone of skin treatment items and convey pure looks.

2. Architectural security and screen result

Content protection : The multi-layer composite framework (external paper appearance + middle barrier layer + internal smooth movie) guarantees high obstacle buildings, efficiently isolates oxygen and wetness, and expands the life span of the item. Dynamic screen benefit : The round tube can roll normally on the shelf or dressing table, showing the brand logo and design from multiple angles, enhancing recognition and screen charm.

3. Environmentally friendly paper material and reinforcing process

Stiffness and durability : Food-grade high-density paperboard is chosen, with a thickness of 270U-400U (personalized), which has superb stiffness and compression resistance, and is difficult to warp and damage during transport and everyday use. Surface area lamination procedure : Environmentally friendly matte/gloss lamination is made use of to boost the fragile touch and visual sense of deluxe, while improving the water resistant and moisture-proof performance, meeting the rigorous requirements of skin treatment items for packaging structure.

4. Hot stamping procedure and color technique

Hot marking information : The text and logo design adopt hot marking innovation to develop a strong metal appeal and three-dimensional comparison on the light blue background, quickly enhancing the delicacy and value of the product packaging, and bring in consumers’ focus. Application of color psychology : The major color is a fresh and soft light blue (Pantone shade number can be personalized), sharing a pure, mild and professional brand name picture, which fits the characteristics of the skin care industry.

5. Effective supply chain assistance

Quick example manufacturing in 1 hour : Relying upon digital mold and mildews and automated assembly line, it sustains very rapid example production, reduces the layout confirmation cycle, and increases the launch of brand-new products. Versatile manufacturing : Supplies full-specification customization with diameters of 13mm-60mm and lengths of 40mm-220mm, with a daily production capability of 300,000 items to satisfy the requirements of set orders.

Recap: Item Core Advantage Contrast Table

| Measurement | Function Description | Technology/Process Support |

|---|---|---|

| Core Style | The round shape is comfortable to hold, and the rolling display enhances acknowledgment | Ergonomic design + vibrant display framework |

| Product and security | Five-layer composite structure (paper base + EVOH obstacle layer + PE lining), compression and damages resistance | High tightness paperboard (270U-400U) + lamination reinforcement |

| Visual Craftsmanship | Light blue primary color + hot marking message, conveying a pure and premium feeling | Pantone color modification + three-dimensional hot stamping procedure |

| Production Efficiency | 1 hour sample, 7-14 days automation cycle, support full-specification modification of diameters from 13-60mm | Digital mold and mildew + automated production line |

| Environmental Accreditation | Paper body make up 80% + degradable lamination, in line with sustainable trends | FSC accredited paper + environmentally friendly layer |

Included worth

Brand name personalization : Sustains balanced out printing/silk screen printing/hot marking and various other multi-process mixes, and can offer complex patterns (such as blossoms, water decreases, personalities) and brand name tale elements. Environmental compatibility : The paper body is recyclable, and the plastic cover (requirements to be handled separately) accounts for just 20%, which is far better than the carbon footprint of all-plastic packaging.