Eco‑friendly cylindrical paper tubes safeguard chargers and power banks with rigid, lightweight construction, customizable full‑color printing, and a secure telescoping lid. Made from 100% recycled fibers and vegetable‑based inks, they cut plastic use by 46%, lower CO₂ emissions, and—with custom foam inserts—ensure premium display and device protection.

Recap

Our bespoke paper tube product packaging service for battery chargers and power banks redefines the requirement for safety, sustainable, and brand-elevating electronic devices product packaging. Engineered with a durable round style, this packaging offers exceptional padding and barrier protection, making certain sensitive digital devices arrive in pristine problem. Crafted from 100% recycled and biodegradable materials, it minimizes dependence on plastic by as much as 46%, lining up with the expanding consumer demand for environmentally friendly products. With a broad selection of customization choices– from full-color offset printing and embossing to indoor foam or molded pulp inserts– our paper tubes permit brands to tell their story in a premium, authentic method. Made under extensive ISO-certified processes, these paper tubes deliver cost-effective, scalable production with the ability of meeting both tiny store runs and high-volume retail needs.

1. Product Overview

1.1 Ingenious Cylindrical Design

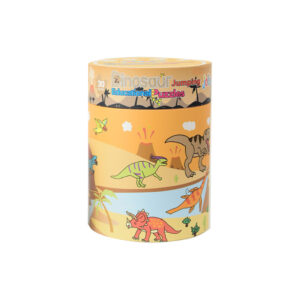

The unique cylindrical kind factor of our paper tube packaging sets chargers and power banks apart on retail racks. Unlike traditional rectangle-shaped boxes, the rounded shape deals:

- Ergonomic Handling : Fits comfortably in hand, improving unboxing experiences.

- Room Efficiency : Enhances shelf realty and stacking security.

- Unforgettable Visual : The smooth surface invites full-wrap graphics for optimal brand presence.

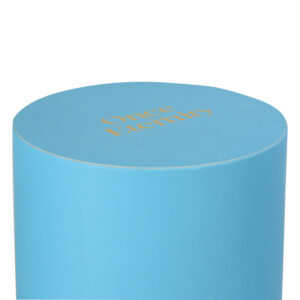

1.2 Costs Brand Name Expression

Our tubes function as a high-impact canvas for brand name narration. Whether showcasing minimal logos or complex graphics, the smooth paperboard exterior supports innovative printing methods– UV place varnish, embossing, and metallic foil stamping– ensuring each bundle radiates luxury and focus to detail.

2. Products and Sustainability

2.1 Eco-Friendly Core

We focus on ecological stewardship by sourcing paperboard tubes made entirely from post-consumer recycled fibers. This selection uses:

- Biodegradability & Recyclability : Tubes can be reused or composted at end of life, closing the materials loop

- Plastic Decrease : By replacing plastic clamshells or boxes, our product packaging cuts plastic material by almost half, equating to significant carbon monoxide ₂ financial savings.

2.2 Certified Sustainability

Our manufacturing partners hold FSC and PEFC qualifications, assuring that basic materials originate from responsibly managed woodlands. In addition, thanks to vegetable-based inks and water-based finishes, our tubes avoid damaging solvents and guarantee secure disposal.

3. Safety Performance

3.1 Structural Stability

The multi-layer spiral-wound construction of our paper tubes provides impressive strength and influence resistance, safeguarding delicate electronics during transit and storage space.

3.2 Padding & Inserts

Complementing the rigid tube wall surfaces, we offer custom die-cut foam or shaped pulp inserts customized to the dimensions of battery chargers and power banks. These inserts:

- Incapacitate devices to avoid moving.

- Take in shocks and resonances.

- Supply an elevated “floating” discussion upon opening.

3.3 Obstacle Coatings

For electronic devices conscious dampness and climatic contaminants, optional interior obstacles deliver hermetic security. Our reduced- to high-barrier finishings extend service life and preserve product integrity for approximately 24 months ([ Sonoco] [5].

4. Modification & Finishing

4.1 Printing Techniques

- Full-Color Offset Printing : Achieve vivid, high-resolution graphics.

- Screen Printing : Perfect for place colors and specialized inks.

- Aluminum Foil Stamping & Embossing : Include tactile and aesthetic accents that convey high-end.

4.2 Surface area Coatings

- Matte or Gloss Laminates : Customize the tube’s surface luster to brand aesthetics.

- Soft-Touch Coatings : Supply a premium tactile feeling, boosting unboxing experiences.

- Spot UV : Highlight specific style elements with glossy accents versus a matte field.

4.3 Configuration Options

- Telescoping Cover : Protect leading closure that doubles as an interior sleeve for added branding.

- Snap-Fit End Caps : Offer tool-free setting up and reusability.

- Die-Cut Windows : Permit customers to see product color or structure prior to acquisition.

5. Production Quality

5.1 Scalable Manufacturing

Our centers flaunt cutting edge spiral-winding equipments with the ability of generating thousands of tubes per hour. Whether you call for brief runs for limited-edition chargers or bulk orders for international circulation, we make sure:

- Rapid Turnarounds : Swift prototyping and tooling configuration.

- Consistent Quality : Automated assessment systems check tube measurements and print stability.

5.2 Quality control

Sticking to ISO 9001 and ISO 14001 criteria, our top quality management systems encompass:

- Inbound Material Testing : Verifying paperboard toughness and dampness web content.

- In-Process Controls : Real-time monitoring of winding stress and adhesive application.

- Last Assessment : Making sure each tube satisfies dimensional resistances and print top quality benchmarks.

6. Tailored Applications for Chargers & Power Financial Institutions

6.1 Retail Ready Product Packaging

- Counter Presents : Tubes stand upright for engaging point-of-sale discussions.

- Sore Substitute : Suitable for brand names transitioning away from plastic pack-ins.

6.2 Direct-to-Consumer Shipments

- Mailing-Grade Resilience : Developed to stand up to messenger handling without second packaging.

- Lightweight Building And Construction : Minimizes delivery prices while keeping protection.

6.3 Occasion & Promotional Kits

- Customized Inserts : Home multiple things– battery chargers, wires, power financial institutions– in one natural package.

- Brand Companion Co-Branding : Integrate logos for joint promos, leveraging the 360 ° printable surface area.

7. Why Choose Our Paper Tube Product Packaging

7.1 Sustainability That Reverberates

By picking our tubes, brand names demonstrate a genuine dedication to lowering plastic waste and lowering carbon impacts, appealing straight to eco-conscious consumers.

7.2 Cost-Effective & Competitive

Compared to plastic or steel choices, paper tubes can reduce product packaging expenses by as much as 50% while using remarkable printability and responsive quality.

7.3 Versatile Branding System

The round layout invites ingenious brand activations– wraparound graphics, hidden messages exposed upon turning, and textured coatings that captivate the detects.

7.4 Robust Supply Chain

With multiple ISO-certified plants and worldwide circulation networks, we assure continuous supply– even throughout peak periods.

8. Final thought

Accept the future of electronic devices product packaging with our Chargers & Power Banks Paper Tube remedy. Integrating environmental integrity, safety efficiency, and unrivaled branding versatility, our packaging boosts your item and highlights your values. Companion with us to provide a long-term impact in every unboxing minute, improve sustainability qualifications, and achieve expense effectiveness– all within a single, ingenious package.

- Ready to redefine your packaging? Get in touch with our team today to request samples, custom prototypes, or a comprehensive quote customized to your Chargers & Power Banks line. *.